FPD Process Equipment

01FPD Process Equipment

Product

Overview of LAT’s Factory Automation System

As for the factory automation, basing on 20 years of accumulated know-how, LAT provides the total solution for automation of CIM-PLC Control Facility area

CIM(Computer Integrated Manufacturing)

Utilizing computer , through total manufacturing system with connection of MES, CIM provides all required information for production line. And it manages line operation recipe and provides tools which monitor status of manufacturing line.

PLC(Programmable Logic Controller)

PLC operates and controls automation the facility of manufacturing line and, it provides solutions for all PLC control protocol, such as Mitsubishi, Omron, LS and etc.

Automation Facility

LAT provides total solution, i.e. consulting, design, electric system and manufacturing, for the automation facility

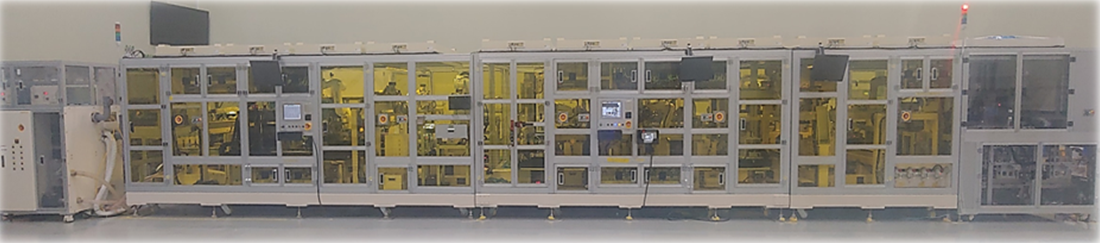

Factory Automation System for FPD(Flat Panel Display) Industry

FPD manufacturing process is done with thin(0.4t~1.27) large size [270mmx360mm(1st generation) ~ 2940mmx3370mm(11th generation)] glass material in the clean room(class100~class1000). Therefore, all manufacturing lines are operated at full automation line. Several processes are bundled and operated like one process, this full automated bundled process line is named as Inline System. LAT’s Inline System has been applied to approx. 500 manufacturing line at domestic and international, and at the line consulting, from line setup to customer service, we provide the best service on them.

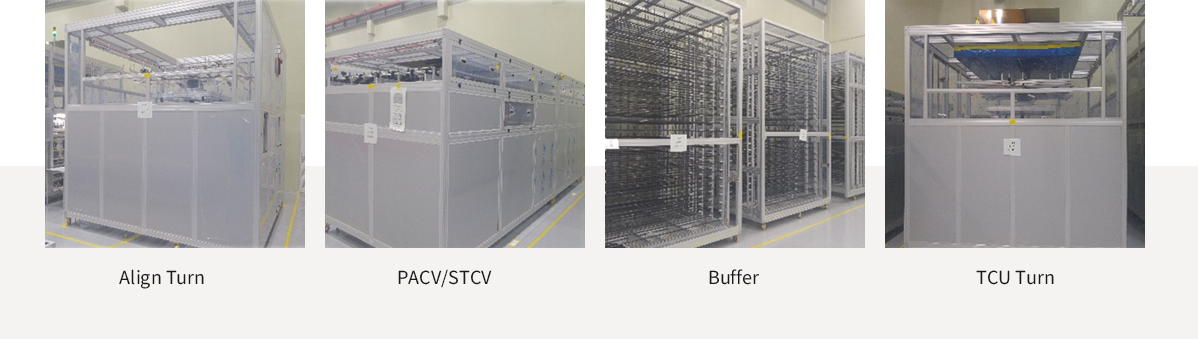

Types of FPD Industry Inline System

| Equipment | Description |

|---|---|

| Indexer (Loader/Unloader) | Facility to input Glass at the Line, which is loaded in the cassette. Glass is handled by robot |

| Feeder | Facility to input Glass which is loaded at Wire-method cassette to Line, it’s for returning Glass to conveyor |

| Robot Transfer Fence (TRF) | Safety fence to control robot for Glass return |

| Conveyor | Basic facility for moving Glass on the plane using the roller. Through combining rotation, reversal and etc., various types of CV’s are available, for example, Divert(Traverse) CV, Turn CV, Pin-up Turn CV, Gate CV, Shuttle CV and etc. |

| Turn Unit | Glass Rotating Unit |

| Turn Over Unit | Glass Reversing Unit |

| Align Pass Unit | Facility to align Glass and robot pass |

| Buffer (BFF) | Facility for Glass loading and storing |

| Wire Buffer | Storage facility to store Glass at Wire Type Buffer, it’s a facility combined with conveyer returning unit |

In-line System

In the LCD manufacturing process, combining equipment of each process, in order to operate all processes like one single system, we have developed the automation system which does hardware and software integrated management. It’s called as In-Line System.

Basing on the know-how of layout setup/design of each process(e.g. Array, C/F, Cell), process operation specification and so on, we provide the total solution to our customers at domestic and foreign.

| Hardware | Software |

|---|---|

|

Design of Production Line Layout Manufacturing & Installation of Production Line Conveyor Facility Automatic Transfer of Panel |

Analysis and Simulation of Production Capacity Specification of Production Line Operation and Device Interface Production Line Operation Software Software for Process and Manufacturing Data Management |

Overview of LAT FPD Processing Equipment

Along with Inline System, LAT proceeded business for FPD(Flat Panel Display) process as well. For the existing energy saving equipment, such as TCU(Thermal Control Unit) and ESU(Energy Saving Unit), we have more than 10 years of accumulated expertise. Recently, we have finished developing 3D Laminator facility for OLED and we collaborate technical matters with customers briskly.

TCU (Thermal Control Unit)

ESU(Energy Saving Unit)

3D Laminator

TCU (Thermal Control Unit)

TCU is a required facility for photo process which is essential process for manufacturing FPD. To prevent Photo Resist, which is coated at the top of glass before exposure, Total-Pitch-Error(Error: Photo Resist’s shape being twisted in accordance with temperature), maintain fixed temperature of glass surface. And TCU regulates expose-temperature condition before exposure. TCU facility is installed at Turn Stage and Robot Fence before exposure, and it may be installed at glass loading Buffer facility as needed. Approximately 180 LAT’s TCUs have been installed in domestic and international, and LAT have experiences of application on all glass generation

ESU(Energy Saving Unit)

ESU is an energy saving unit, which is used during FPD manufacturing process. ESU uses wasted hot air from hot air oven, and it is a kind of heat exchange unit, which heats clean air before inputting in the oven. And ESU unit itself does not need energy, wasted air and clean air are separated completely, therefore, no air pollution on input air. Most of all, through the maximum heat transfer effect, 50% of electric energy on oven can be saved

3D Laminator

Among the OLED Display Panel manufacturing process, 3D Laminator is the facility which is used for laminating 3D shape’s Cover Glass and flexible material’s OLED Panel. And it is consisted of 3D shape Flexible Pad/Vacuum Chamber, and OCR(Optical Clear Resin) Coating or OCA(Optically Clear Adhesive) Film laminating unit, and it is a compound technology facility which minimizes damage on high precision and high priced OLED Panel Recently, LAT completed demonstration model of the 3DLaminating, and we do marketing activity for the product on our major customers for mass production